GATE C is a circular economy consulting firm

GATE C is a circular economy consulting firm. We help businesses to map the benefits and capture the value of the circular economy. Since 2012, our consultants have conducted more than 300 circular economy consulting assignments. We are part of the Ellen MacArthur Foundation community.

Our latest news

In 2025, GATE C has been recognized by ClimateSort as one of the world’s Top 12 Circular Economy Consulting Companies.

UBER Eats partnered with GATE C to develop an environmentally aware packaging framework for restaurants in France, and help restaurants make informed decisions for their business.

The Royal Society of Chemistry recently published an analysis of the wind energy industry’s material requirements based on research conducted by GATE C.

Our circular economy consulting services

Circular sourcing

We help purchasing departments to adopt circular sourcing strategies to reduce costs, secure supplies and save resources.

Circular factory

We work with production departments to better capture the value of industrial waste.

Digital circular economy

We help businesses to fill the information gap to enable the transition toward a circular economy.

Alternatives to plastic

We help companies to find alternative materials, packaging or distribution models to reduce plastic consumption for packaging. Learn more.

Circular evaluation

We designed a circular framework to help our clients understand how far they are from becoming a circular company. Learn more.

Circular training

We deliver training to build our clients’ capabilities. Our training program features three modules that can be customised to our client’s needs. Contact us to learn more.

Getting ready for the CSRD

The Corporate Sustainability Reporting Directive (CSRD) requires 50,000 companies in the EU to disclose data related to resource use and circular economy. What is ESRS E5, resources use and circular economy? How to prepare for the disclosure? And how we can help.

Switching to reusable packaging

Pressured by increasing regulations, producers need to switch to reusable packaging. However, barriers to reusable packaging are multiple. How to switch to reusable packaging? And how we can help?

circular economy consulting: Our clients

We provide circular economy consulting services mainly to corporations, from a wide range of industries. We also work with territories and business associations. Our clients include:

Testimonies

Our newsletter

Subscribe to our monthly newsletter to stay current with the latest circular economy insights and our consulting work.

Featured Insights

For a circular energy transition

Exponential demand for critical materials, driven by the energy transition, may trigger supply chain problems. Circular economy business models could help decouple the renewable energy sector from material consumption. However, facing major economic, regulatory and financial barriers, the transition of the sector towards a circular economy still has a long way to go. In our report for the Green Purposes Company, we propose an action plan for the renewable energy sector to be fully aligned with the principles of a circular economy and reap its benefits.

The materials industry needs to transition to a circular economy

The materials industry is a major source of CO2 emissions. To reduce these emissions, it needs to transition to a circular economy.

Digitalising material flows

The power of digital technologies to enable the circular economy. Print version

Can developing countries benefit from the circular economy?

Developing countries have not benefited from the linear economy. Can that change with the circular economy? Print version

Remaining at the top of the political agenda

We asked the former European Commissioner for the Environment, Janez Potočnik, how can the circular economy remain at the top of the political agenda.

Could circular economy help businesses face the worst recession ever?

During the Covid-19 pandemic, circular economy helped hospitals face supplies shortage. Can it help businesses face the worst recession ever?

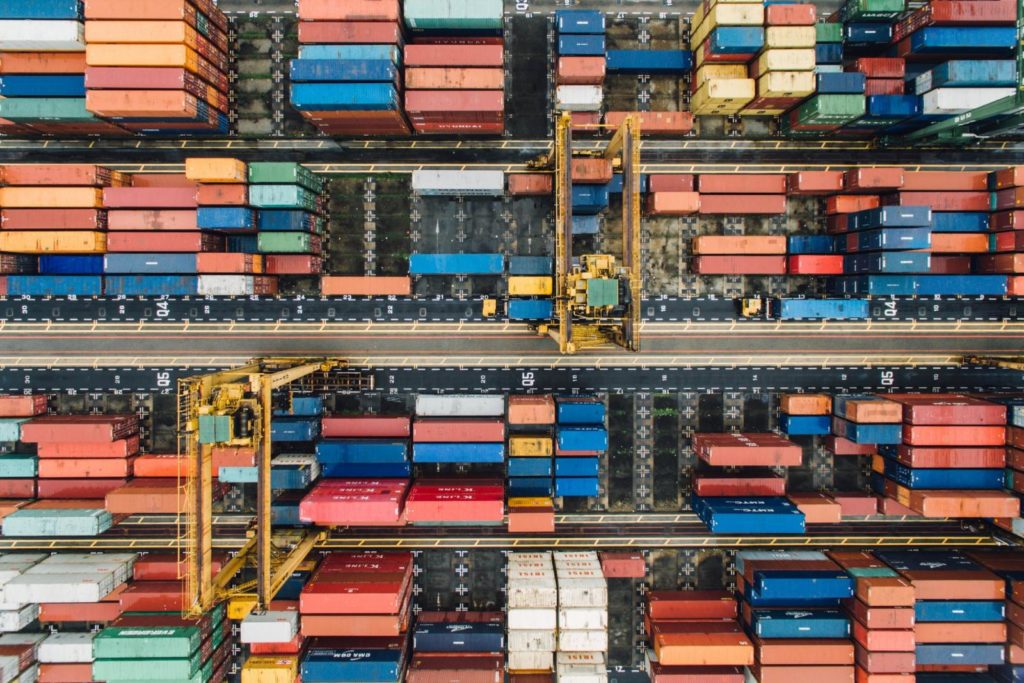

Reverse logistics, the circular economy weakest link

Reverse logistics is sometimes described as the logistics going in the “wrong direction”. Yet it plays an important role to transitioning to a circular economy.

Waste watchers

For factories, applying circular economy strategies could create cost-saving opportunities and profitable new revenue streams.

Toward factories with no assets

Today, many factories are using energy service companies to improve their energy efficiency.

Tomorrow, they will very likely buy pay-per-use services to improve their resource efficiency.

Waste + Information = Resource

To maintain the value of materials and products in the economy for as long as possible, the circular economy needs to have access not only to waste but also to information regarding said waste.

The machines that predict the future

Thanks to predictive maintenance, products can forecast failures before they occur.

Circular molecules

The circular economy and digitalisation will be the two most important trends employed by Germany’s chemical industry as it moves towards 2030.

Making products last

Thanks to remanufacturing, refurbishing and repair, products are not just consumables anymore, they become assets, our assets.

Chemical leasing

Chemical Leasing is a performance-based (service-oriented) business model that shifts the focus from increasing sales volume of chemicals towards a value-added approach.

Circular procurement

To improve material efficiency, purchasing departments could leverage circular economy.

Creating jobs, saving resources

For decades, companies have improved labour productivity to reduce their costs. But, they should rather focus on resource productivity, and create jobs.

Reducing hospitals cost

Unlike many other sectors, hospitals have not yet fully optimised their production resources. But that can change.

Fixing broken supply chains

By implementing circular economy strategies, businesses could build more resilient supply chains

Ending e-waste

Waste electrical and electronic equipment is currently considered to be one of the fastest growing waste streams in the European union, growing at 3-5 % per year. That needs to change.

Circular economy, strategy for a sustainable world

Our book, in French, is a practical guide for companies willing to transition towards a circular economy. Read an extract here.

Pay-per-use chemicals

A growing number of chemical companies offer to sell not their chemicals, but the service those chemicals provide.

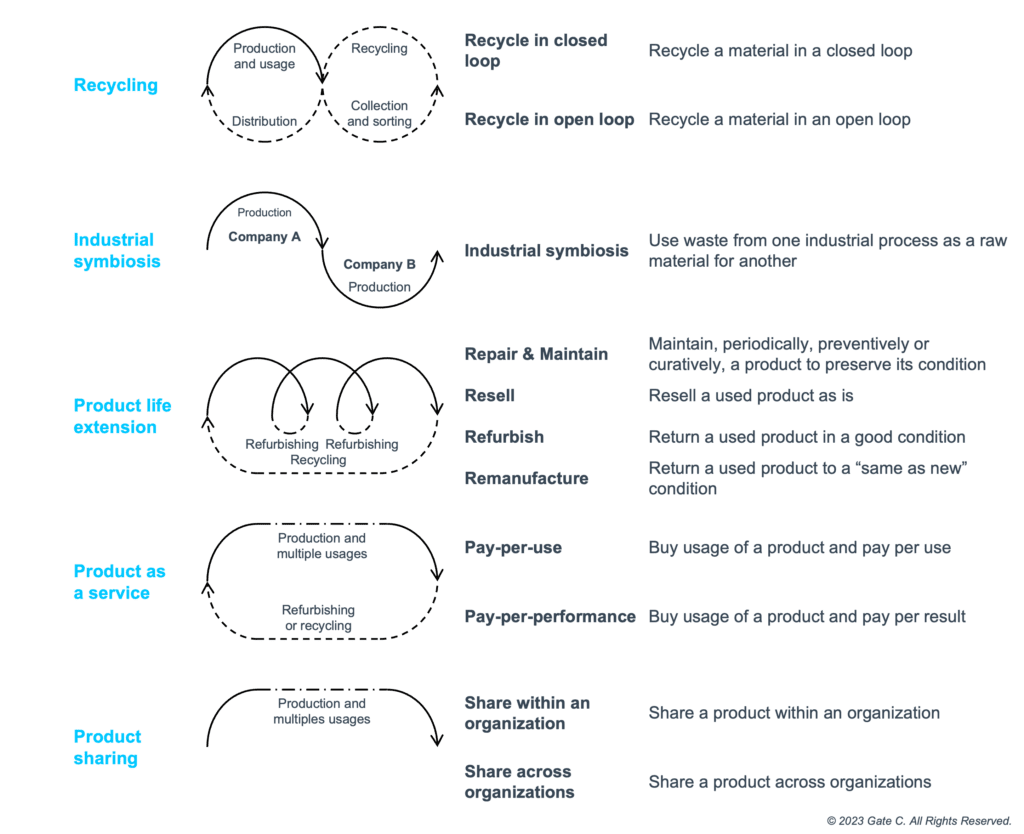

Circular business model

Manufacturers must adopt circular business models to reduce costs, decrease CO2 emissions, and secure critical materials supply.

In the press

Featured Capabilities

We offer proprietary tools and databases to accelerate and increase impact, such as:

Circularity indicators

Businesses need to define indicators to track their transition toward a circular economy. We help our clients set clear KPIs by choosing them from our repository of more than 100 qualified circularity indicators.

Matchmaking platform

We use a digital platform to match waste supply from one industrial process with raw material demand from another. The platform leverages big data and machine learning technologies.

Reverse logistics maturity model

The model assesses the reverse logistics maturity level. It describes the characteristics of successful reverse logistics processes across multiple dimensions.

Circular card game

To help our clients design circular solutions, we designed the circular economy card game. Cards describe all the possible circular business models, circular products and circular ecosystems. View some cards (in French).

Circular business models

We have identified 5 circular business models that are generating resource productivity improvements.

About us

We are a consulting firm specialised in circular economy. We have led more than 300 circular economy projects in the last 10 years. GATE C is managed by Rémy Le Moigne and Maya Laredo. Our team of 5 consultants combine extensive experience in management consulting, sector expertise and the circular economy. We are located in Paris, France but work internationally.

We are part of the Ellen MacArthur Foundation community.