SWITCHING TO REUSABLE PACKAGING

WHY REUSABLE PACKAGING?

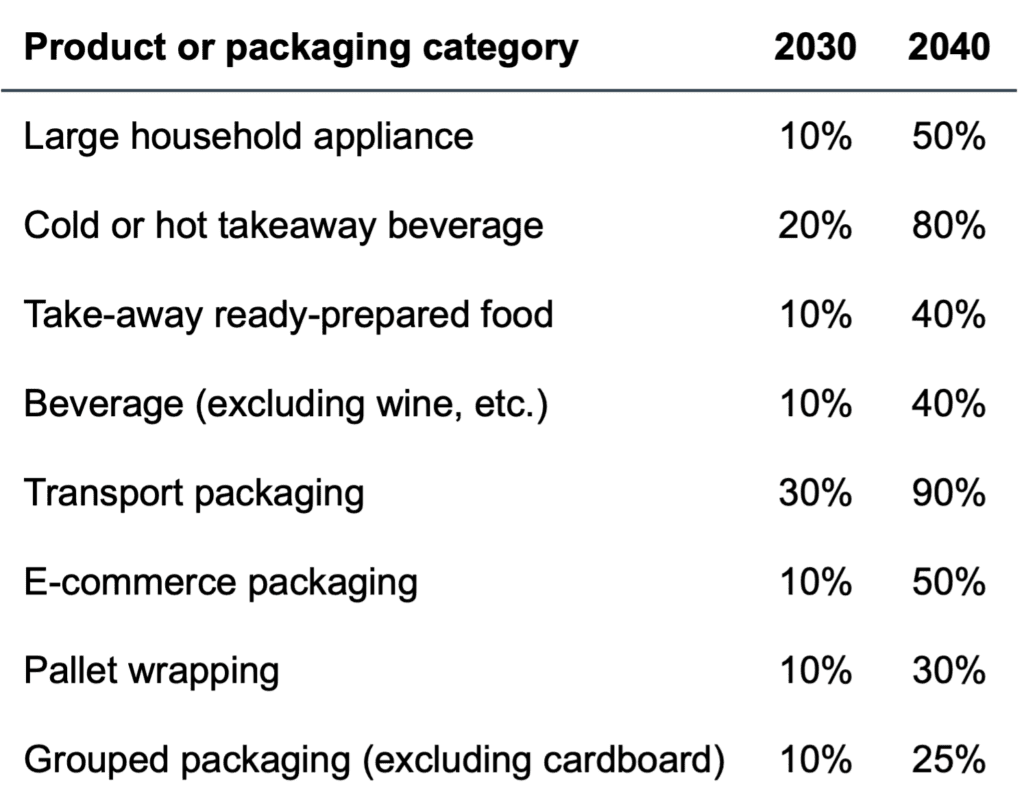

Facing a tsunami of regulation at national and regional levels, manufacturers and distributors are switching to reusable packaging. For example, the proposed regulation on packaging and packaging waste from the E.U. is setting ambitious reuse targets.

HOW TO SWITCH TO REUSABLE PACKAGING?

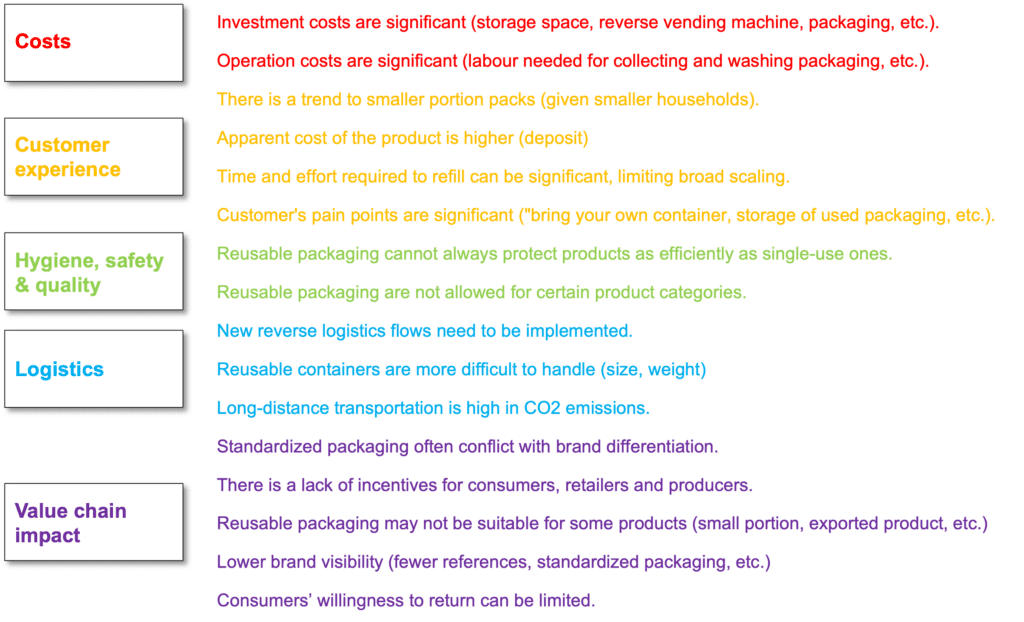

Switching to reusable packaging faces multiple barriers.

HOW WE CAN HELP

We support our clients in designing reusable packaging solutions.

Training

We deliver a one-day training on reusable solutions. The training includes more than 50 case studies and examples.

Workshop

We prepare and facilitate workshops gathering marketing, sales, packaging and purchasing representatives, to identify relevant reusable solutions.

Solution design

We help our customers qualify reusable solutions: barriers to address, enablers to consider, partnerships to establish, costs and benefits, and environmental impact.

Cases studies

For ADEME, we analyzed the development potential of packaging reuse by sector. For each sector, we identified barriers and levers.

For the Fédération des Entreprises de la Boulangerie (bakery-pastry chains and producers), we designed a roadmap to phase out single-use plastic packaging by 2040 and adopt reusable packaging.

In partnership with Emballages Magazine, we organized training on reusable packaging. The training includes presenting more than 50 case studies and case examples.

Our methodology

We developed a 5-step methodology to support our customers in adopting reusable packaging. Please complete the form below to download our methodology presentation.