Circular sales

HOW TO SELL THE SAME PRODUCT MULTIPLE TIMES?

At GATE C, we help sales and marketing departments recover, prepare for reuse, and resell their products. Often underestimated, circular sales represent a significant opportunity to increase revenue.

A product prepared for reuse, reconditioned, or remanufactured, is less expensive than a new product. For example, remanufactured Massey Ferguson tractor engines cost 30% less than new ones, while offering the same performance and warranty. TeliaSonera, a telecommunications company, preferred to have its used office furniture reconditioned rather than buying new. Rather than buying new refrigerated cabinets, retailers M&S, COOP, and Sainsbury’s have their used cabinets reconditioned.

The expected increase in the price of carbon will likely contribute to increasing this price gap. For example, if the carbon price were set at $50 per tonne, a new compressor worth $79.50 would cost only $5.85 remanufactured. 5

A reconditioned product is therefore an attractive alternative to low-cost products. By reconditioning its products, a company can access the market of customers who cannot or do not want to buy new products. For example, by selling reused spare parts, Renault was able to access customers who did not want to buy new parts for their old vehicle. A furniture manufacturer estimated that it could increase its turnover by 95% on the sale of a sofa by reselling it three times in a row and then reselling its materials. The distributor Electro Dépôt has set itself the objective that the sale of reconditioned and used products as well as rentals will represent 40% of its turnover by 2035.6

The sale of products prepared for reuse, reconditioned or remanufactured is growing in many economic sectors.

20%

Share of second-hand

smartphones used in France in 20251

$100

Global refurbished electronics market estimated to be worth billions

in 20302

10%

Annual growth of the global second-hand

clothing market3

5%

Minimum annual growth of the global market for the reuse and remanufacturing of

industrial equipment4

OBSTACLES TO CIRCULAR SALES

The sale of products prepared for reuse, reconditioned or remanufactured, nevertheless faces significant obstacles.

Cannibalization of sales

Companies may be hesitant to market products whose sales could cannibalize those of their new products. However, the risk of cannibalization is often limited. Refurbished products compete more with low-cost products than with new products.

To reduce the risk of cannibalization, manufacturers can use a specific distribution channel, market refurbished products under a specific brand, or sell their refurbished products in new markets.

Availability of used products

Companies can adapt the production of new products to meet demand. However, the marketing of reconditioned products depends on the availability of used product reserves, which the company has no control over. These reserves often vary in volume and quality.

Customer acceptability

Customers may be hesitant to purchase products that aren’t new, especially high-value and technical products. A reused product may be perceived as less reliable, less safe, or less durable than a new product. Sometimes it is.

The buyer must ensure that the performance of the reconditioned equipment will meet their expectations (supplier warranty, certificate, etc.). In France, the reuse federation offers the RecQ Quality Reconditioning label.

Products not designed for reuse

Not all products are designed for reuse.

A product intended to be reused multiple times must be designed with reuse in mind. Parts and components that may be replaced during the product’s lifetime must be easily accessible. Visible parts should be made of materials that are not very susceptible to scratches. It must be possible to quickly and irreversibly erase personal data stored in the product. For example, most smartphones offer a function that allows you to reset the phone to delete all personal data.

HOW WE HELP OUR CLIENTS

Evaluate the market and its customers

Evaluate the size of the market for products prepared for reuse, reconditioned or remanufactured

Define distribution channels

Identify distribution channels to avoid the risk of cannibalization

Addressing barriers to marketing

Identify the main obstacles to marketing and the levers to mitigate them

Confirm the business case

Evaluate production costs (collection, sorting, reconditioning and distribution of used products) and customers’ willingness to pay

Our cases studies

For a global office furniture manufacturer, we designed a refurbished furniture sales offering. We compared different business models and assessed the return on investment.

Our client subsequently set up a refurbished furniture offer.

For the eco-organization Ecomaison, we assessed the supply and demand for furniture repair services. We identified the main breakdowns and repairs by furniture category (kitchen and bathroom, sofa and armchair, furniture, outdoor furniture).

Ecomaison subsequently set up a network of sofa repairers and a repair bonus.

For Bpifrance, we evaluated the different models for sorting, recycling and reuse of construction materials (grouping platform, digital platform, etc.) to resell used construction materials.

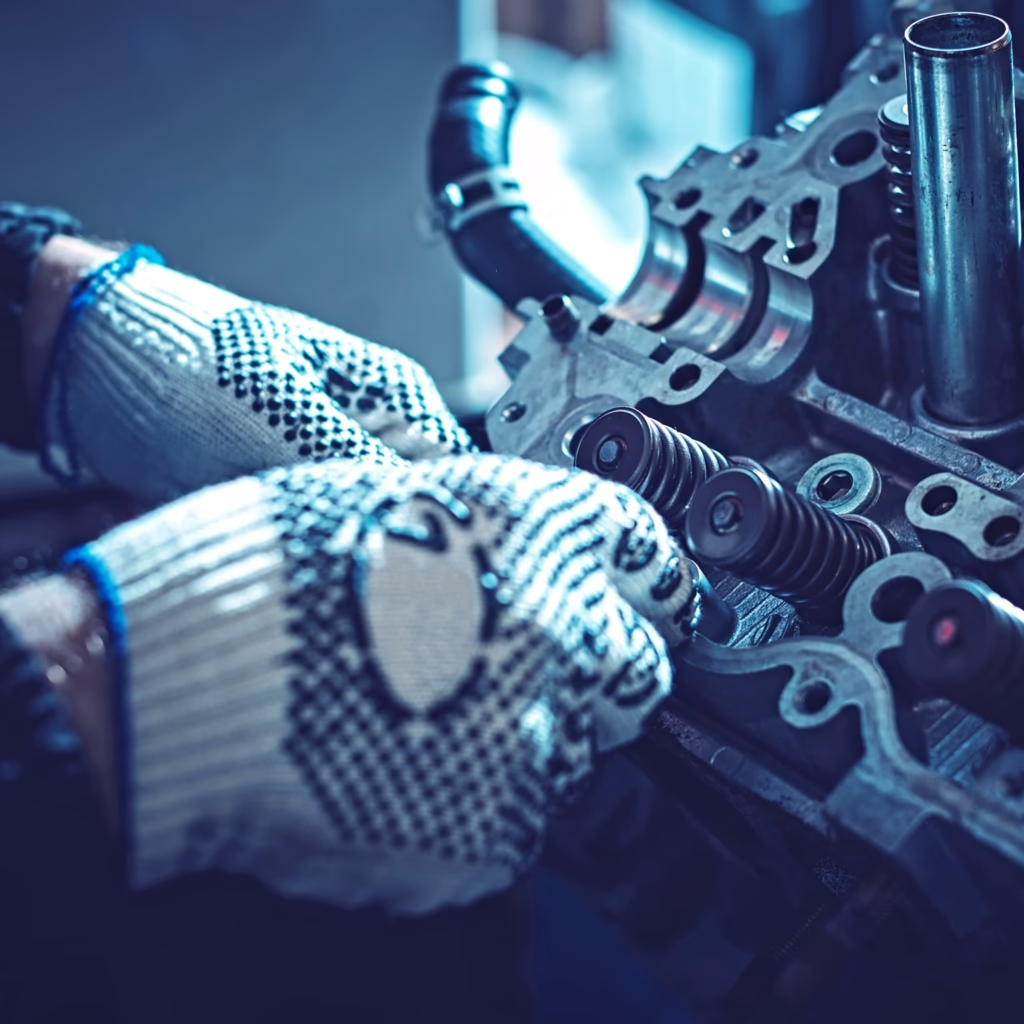

For an industrial equipment manufacturer, we supported the implementation of a range of reused spare parts.

Our client now collects, refurbishes and then resells spare parts that are no longer available new.

For a manufacturer, we studied the opportunity to increase the value of its dormant stocks by selling them on the Leboncoin platform.

Leboncoin records nearly a million daily visits to its categories dedicated to professional equipment.

Connect with our circular economy consultants to know more