Circular production

Why a circular production?

Often underestimated, the cost of manufacturing waste management is significant and increasing.

Sort & store

As with finished products, waste sorting and storage come at a cost. For example, renting a baler can cost up to €500 per month.

Collect

Each year, the French economy spends 7.1 billion euros on waste transportation.

Dispose

In most countries, disposal costs are increasing. In Austria, the landfill tax rose from €3 to €87 per ton between 1996 and 2014. In the UK, the actual cost of industrial waste typically accounts for 4% to 5% of turnover and can be as high as 10%.

To better capture the value of industrial waste, factories should leverage circular economy business models.

How we help our clients?

Train employees

We deliver training on zero-waste factories, leveraging more than 150 examples and case studies.

Capture the value of waste

We assist our clients in identifying the most relevant circular economy business models for waste management.

Convert waste into byproducts

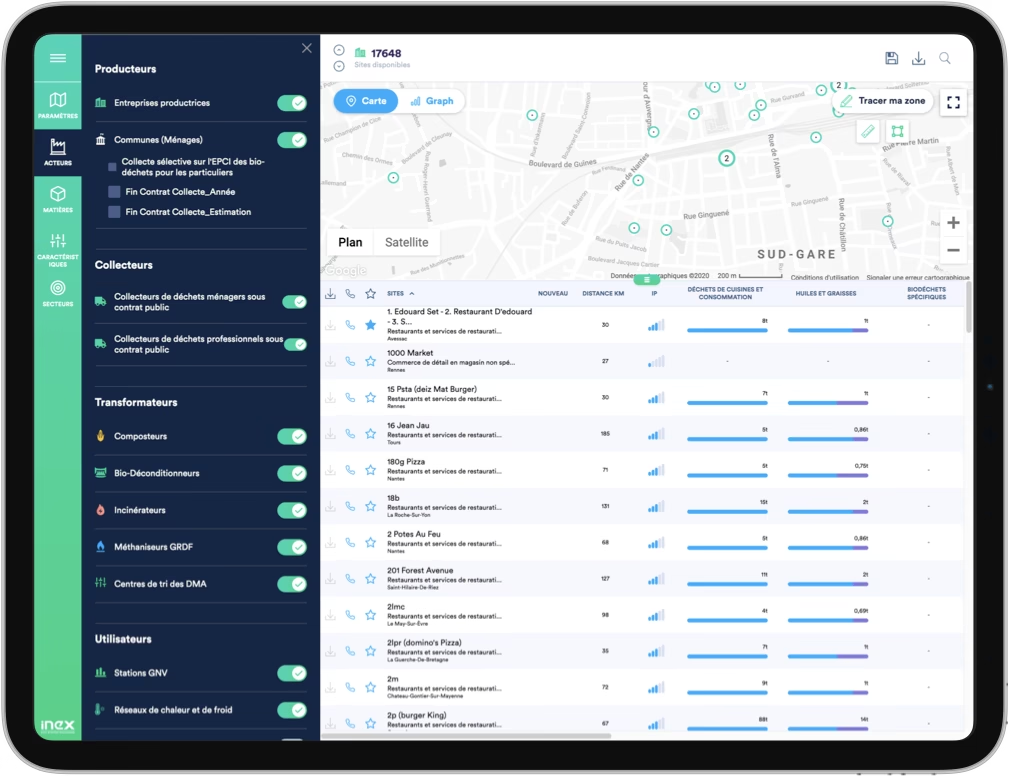

We use a digital platform to match waste supply from one industrial process with raw material demand from another, turning ‘waste into wealth.’ The platform leverages big data, statistical analysis, and machine learning technologies.

Cases studies

For a consumer products manufacturer, we evaluated several opportunities to reduce industrial waste, including chemical leasing and waste recycling. We found that chemical leasing could reduce total cost of ownership (TCO) by 15%.

We helped a chemical plant resell its waste as a resource to other industries. As a result, our client reduced waste management costs by €0.5 million per year.

Featured capabilities

We use a digital platform to identify how waste from one industrial process can be used as a resource for another. The platform leverages advanced technologies such as big data and machine learning.

FEATURED INSIGHTS

Waste watchers

For factories, applying circular economy strategies could create cost-saving opportunities and profitable new revenue streams.

Toward factories with no assets

Today, many factories are using energy service companies to improve their energy efficiency.

Tomorrow, they will very likely buy pay-per-use services to improve their resource efficiency.

Connect with our circular economy consultants to know more