Circular chemicals

To improve both economic and environmental performance, companies should reuse chemicals more than once.

Why a circular chemicals?

The use of chemicals in industrial processes is often economically and environmentally inefficient.

Purchase

Most companies are unaware of the total cost of ownership of the chemicals they purchase. Yet, for every euro spent on chemicals, an additional €5 to €10 is spent on managing them.

Use

In many cases, chemical efficiency is alarmingly low, with yields often below 50%. This means that up to half of the chemicals become waste without ever being used. In some industrial processes, chemical yield can be as low as 5%.

Dispose

For disposal, spent chemicals must be converted into water, which can be discharged, and waste sludge, which is either incinerated or landfilled. This conversion process requires additional chemicals. In pharmaceutical manufacturing, at least 25 kilograms of emissions and waste are generated for every kilogram of product.

To better capture the value of chemicals, companies should adopt strategies that enable molecules to be used more than once.

How we help our clients?

To help our clients leverage circular sourcing strategies, we offer a comprehensive set of services.

Training

We deliver training on circular strategies for chemicals, leveraging more than 150 examples and case studies.

Capturing the value of chemicals

We assist our clients in identifying the most relevant circular economy business models for managing chemicals.

Converting waste into byproducts

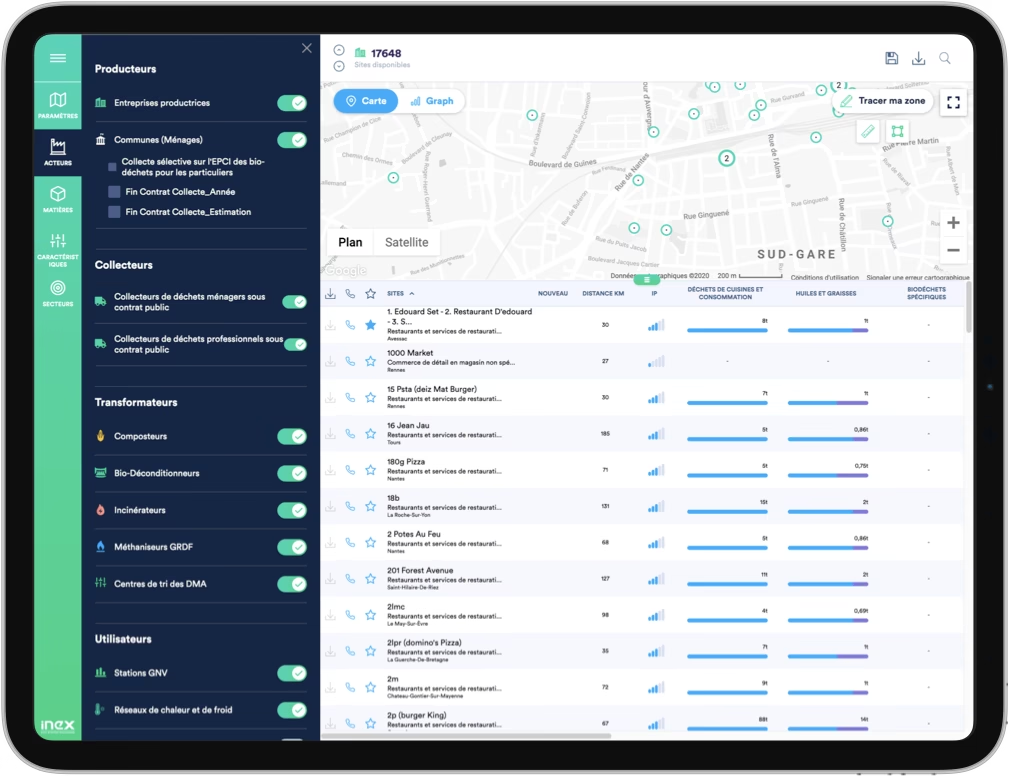

We use a digital platform to match waste supply from one industrial process with raw material demand from another, turning ‘waste into wealth.’ The platform leverages big data, statistical analysis, and machine learning technologies.

Leasing chemicals

We assist our clients in switching to a pay-per-use business model. We use a robust methodology: the Chemical Leasing Toolkit, developed based on UNIDO’s experience with chemical leasing projects.

Cases studies

For a consumer products manufacturer, we evaluated several opportunities to reduce industrial waste, including chemical leasing and waste recycling. We found that chemical leasing could reduce total cost of ownership (TCO) by 15%.

We helped a chemical plant resell its waste as a resource to other industries. As a result, our client reduced waste management costs by €0.5 million per year.

For a pharmaceutical group, we delivered training on circular economy business models for chemicals to 30 representatives from sales, production, and purchasing departments.

One of our clients, a consumer-packaged goods manufacturer, used hydrochloric acid for its surface treatment processes, resulting in high acid disposal costs. We identified a low-cost solution to remove impurities from the spent acid and extend its useful life. As a result, our client reduced spent acid disposal costs by 20%.

Featured capabilities

We use a digital platform to identify how waste from one industrial process can be used as a resource for another. The platform leverages advanced technologies such as big data and machine learning.

FEATURED INSIGHTS

Circular molecules

The circular economy and digitalization will be the two most important trends driving Germany’s chemical industry as it moves towards 2030.

Chemical leasing

Chemical Leasing is a performance-based (service-oriented) business model that shifts the focus from increasing sales volume of chemicals towards a value-added approach.

Connect with our circular economy consultants to know more