What is a circular business model?

What is a circular business model? Why will manufacturers have to adopt the new business models of the circular economy to reduce their costs, reduce their CO2 emissions and secure their supplies?

This article was originally published in Futuribles.

The strong population growth and its concentration in urban areas will lead to a very strong increase in the demand for raw materials. Access to natural resources with limited reserves will become increasingly difficult and competitive. The demand for water alone is expected to exceed the available reserves by 40% by 2030 [1].

In anticipation of difficult access to resources, manufacturers are launching initiatives to use them more efficiently: they reduce their waste production, limit their water consumption or design products that are less material-intensive. This optimization of industrial models is necessary but it will not be enough. Current business models will eventually show their limits in a world with finite resources.

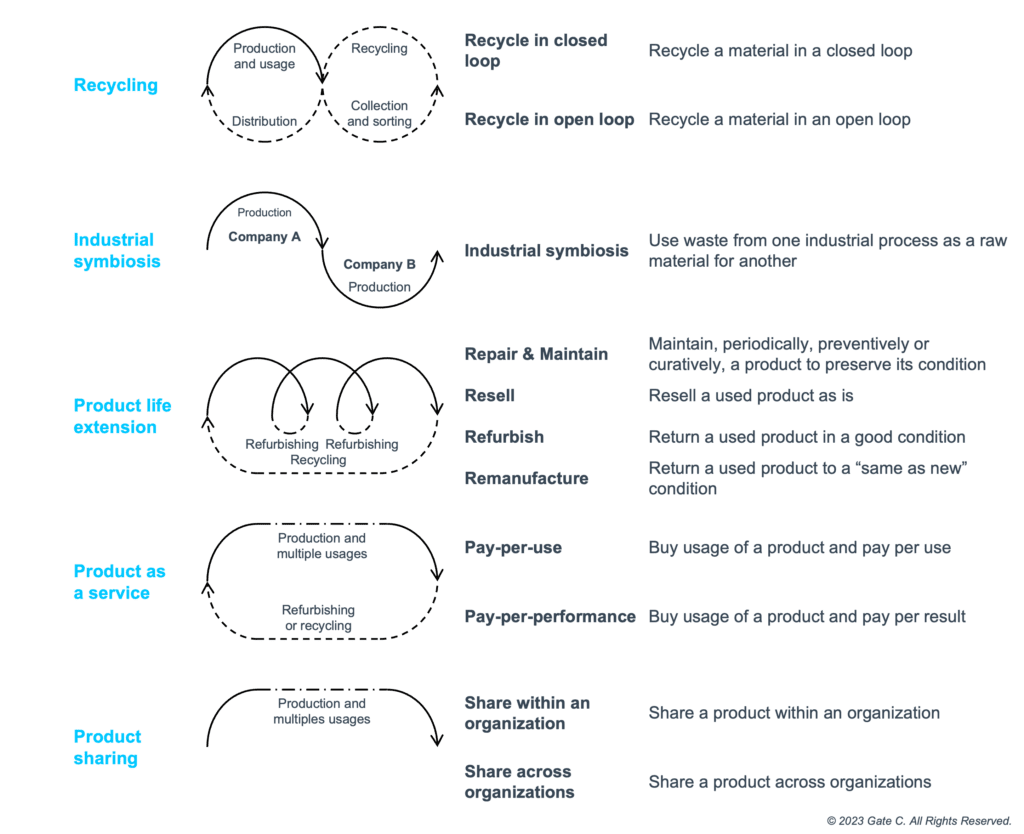

Industries will have to adopt new business models, business models that manage resources in a loop through reuse, repair, remanufacturing or recycling: the business models of the circular economy (see figure).

The long-loop recycling model makes it possible to recover the materials contained in end-of-life products. In this model, production and usage flows are not synchronized with recycling flows. Products that arrive at the end of their life are collected and then sorted. Technical materials, such as metal or plastic, are recycled while organic materials, such as cotton, are composted or methanized. This model, often implemented for consumer products, is generally inefficient: the recycling of mobile phones, managed in a long loop recycling model, has a yield of less than 5% [2].

Unlike the previous model, short-loop recycling model allows much higher recovery rates to be achieved. In this model, the location and condition of the products are constantly monitored. As soon as the product reaches the end of its life, its material is recovered to make a new product. Oil refineries often partner with metallurgical companies to manage the recycling of catalysts in a short loop. This recycling, which allows the recovery of precious metals such as palladium or platinum, typically achieves yields above 90% [3].

However, most often, recycling allows only a small part of the value of a product to be retained. For example, the recycling of an iPhone retains only 0.24% of its value [4]. On the other hand, its reuse can 48% [5]. The extension of the life of products is therefore often preferable to recycling. For its life to be extended, a product must generally be repaired after each use. The repair can vary from a simple cleaning to the disassembly and then complete reassembly. Like Caterpillar, Rockwell Automation or Siemens Healthcare, more and more manufacturers are recovering their used products from their customers to repair them and then resell them again (or to recycle them if the products cannot be repaired).

The circular economy applies not only to finished products but also to production waste. Often manufacturers seek to get rid of their production waste at a lower cost. However, it is possible to recover this waste by setting up industrial symbiosis. In an industrial symbiosis, waste from one manufacturing process is used as raw materials for another. Grey water from a manufacturing line can be reused for cleaning. Fruit pulps and peels, co-products of juice production, make it possible to make dietary fibers. Potato starch, a co-product of the manufacture of wallpaper glue, is part of the composition of bioplastics. The identification of industrial symbiosis within a territory is carried out as part of an industrial ecology project.

A company may prefer the sale of the use of a product to that of the product itself. Indeed, by remaining the owner of his product, he can better retain control and preserve its value. For example, Philips sells not lighting systems but light to municipalities. The company remains the owner of the equipment and bills the light to the municipalities. Once they reach the end of use, the lighting systems are repaired or recycled. The sale of the use of a product (sometimes called performance economy) leads manufacturers to develop sustainable and easily maintained products.

Finally, sharing the use of a product allows several users to share the use of the same product. It is often made possible by sharing platforms (such as websites or mobile applications) that connect users to sell, exchange, rent or give goods or services. Sharing can be organized by a community of users or a private company such as BlaBlaCar (carpooling), Zilok (product rental), Patatam (purchase and resale of children’s clothing) or Airbnb (housing rental). This model, also called collaborative consumption or sharing economy, is suitable for products whose use rate over the total lifespan is low, such as cars, housing or clothing. According to a recent study by the IDDRI (Institute of Sustainable Development and International Relations), sharing the use of a product would not always make it possible to obtain the expected environmental impacts [6].

These different business models are not exclusive. Renault, for example, recycles materials such as plastic or metal, remanufactures its mechanical parts to extend their life and sells the use of its electric batteries. Initial feedback has shown that the new business models of the circular economy are disrupting the balance both within companies, but also within their supply chain. Companies that implement a circular economy strategy and these new models will therefore have to face many resistances. But they are the ones who will imagine the companies of tomorrow in a world with finite resources.

FAQ ON CIRCULAR BUSINESS MODELs

There are five business models of the circular economy:

– the management of materials in long or short loops,

– the extension of the life of products,

– the exploitation of industrial symbiosis,

– the sale of the use of a product,

– sharing the use of a product.

For several decades, manufacturers have been leading initiatives to use resources more effectively, access to which will be increasingly competitive. They reduce their waste production, limit their water consumption or design more material-efficient products. These incremental optimizations of current industrial models are necessary, but they will not be enough. Between 1995 and 2010, phosphorus extraction increased by 30%, iron production by 81%, plastic by 83% and carbon emissions from fossil fuels by 48%. Current business models show their limits in a world with finite resources. Industrialists will have to adopt new business models, the business models of the circular economy.

Connect with our circular economy consultants to know more